In recent decades, diesel engines have undergone tremendous changes, with higher horsepower, higher fuel efficiency and better reliability. With the development of technology, most of the engines are equipped with a high pressure common rail fuel system (HPCR), which requires a higher pressure of 2000 bar and stricter tolerance.When organic or inorganic contaminants, including water, and impurities penetrate into the fuel supply system, fuel components are prone to damage. The key component to prevent these potential hazards is the diesel filter.

The diesel filter knot is roughly the same as the oil filter structure, and is also divided into a replaceable type and a rotatable type.

However, the working pressure and oil temperature resistance required are much lower than that of the oil filter. As the engine oil, the oil can reach a temperature of up to several hundred degrees Celsius. The high temperature resistance of the oil filter is naturally important, and the fuel filter is important. Simply meet the natural ambient temperature and the fuel supply is smooth.

The filtration efficiency requirement is much higher than that of the oil filter. This is due to the accuracy of the engine fuel injection system. The fuel injection pressure of up to 2000 bar, the fuel is already fully atomized, and a trace of impurities will cause the injection system. The blockage is even the scrap of the fuel injector. It is this requirement that determines the difference in the structure of the diesel filter.

Diesel filters can be classified into diesel strainers, diesel water separators, and diesel fine filters according to their functions.

Diesel strainer: As the name implies, the main function is to initially filter the relatively large impurities in diesel fuel, which is usually installed in the fuel tank.

Oil-water separator: The main function is to separate the water in the diesel oil. The presence of water is extremely harmful to the diesel fuel supply system, and rust, wear, jamming and even worsening the combustion process of diesel. Moreover, China’s diesel fuel has a high sulfur content, and it is easy to react with water during combustion to produce sulfuric acid, which corrodes engine parts. Under the national standard, diesel fine filter is mainly used to filter impurities of 3-5μm in diesel oil, which is the main filter component. The oil-water separator and fine filter are usually installed outside the fuel tank for easy observation and maintenance.

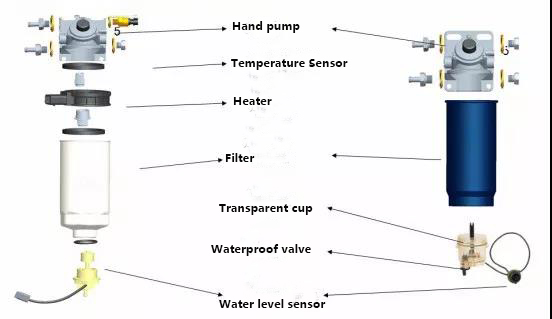

With the development of truck technology, engineers of fuel filtration systems have integrated many functions. For example, the oil-water separator and the fuel fine filter are combined into one to realize the effective use of space. Sensors and fuel heaters are installed on the fuel filter to monitor fuel quality in real time to meet the stability of the fuel supply system in cold conditions.

The internal structure of the diesel filter is composed of filter paper, bypass valve, pressure limiting valve and oil drain plug. The principle of action is the same as that of the oil filter, but the filter efficiency of the diesel filter is higher. More rigorous and more advanced in structure. Commonly used composite materials, more advanced nano-scale materials, can maintain more than 95% of oil-water separation efficiency, dust-proof rate is also 3.5 times higher than the average.

As a common consumable for trucks, diesel filters are constantly innovating and the structure has been optimized. However, the best product structure is still inseparable from the reasonable maintenance of the driver’s friends. During the daily driving process, more observations, more attention, and maintenance. This will ensure that the truck’s “kidney” (diesel filter) is safe and efficient, and the engine is durable, thus reducing the overall transportation cost of the driver’s friends.

Post time: Dec-06-2018