The air filters on automobiles are very familiar to everyone. Some of them have strong practical ability and are often maintained and replaced by themselves. But some people may be thinking: Why is there only one set of air filters on the car? Wouldn’t it be possible to filter the air cleaner if two sets of air filters were set up? Is this the only type of air filter? If the dust is very big, this thin paper filter will soon dirty, what should we do? Now let’s talk about this topic. First of all, there are many models using two sets of air filters. The trucks and engineering machinery we saw on the road are almost two sets of air filters, and they are not all paper. Some models strictly calculate that the air has to be filtered three to four times, and some off-road vehicles used in special areas also use two sets of air filters to prevent excessive dust and impurities in the air from entering the engine. For ordinary family passenger cars, only one set of air filter is enough.

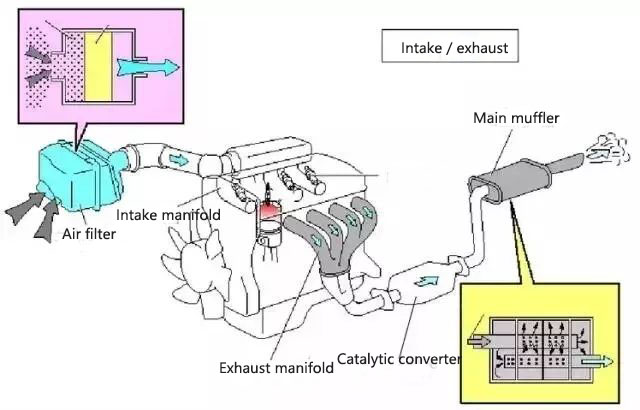

First of all, there are many models using two sets of air filters. The trucks and engineering machinery we saw on the road are almost two sets of air filters, and they are not all paper. Some models strictly calculate that the air has to be filtered three to four times, and some off-road vehicles used in special areas also use two sets of air filters to prevent excessive dust and impurities in the air from entering the engine. For ordinary family passenger cars, only one set of air filter is enough. The function of air filter is well known. Like the gas mask of an engine, it isolates the harmful substances such as dust and sand suspended in the air from the engine, so as to make the engine breathe cleaner. If air is sucked into the cylinder without being filtered, the wear of the piston set and the cylinder will be accelerated; if the larger particles enter between the piston and the cylinder, it will cause serious “cylinder pulling” phenomenon, leading to early engine damage. I have personally dealt with several early engine failure caused by air filter damage, which is very dirty inside the engine, thick sludge attached to the parts, piston rings jammed, cylinders worn seriously, showing typical abrasive wear symptoms.

The function of air filter is well known. Like the gas mask of an engine, it isolates the harmful substances such as dust and sand suspended in the air from the engine, so as to make the engine breathe cleaner. If air is sucked into the cylinder without being filtered, the wear of the piston set and the cylinder will be accelerated; if the larger particles enter between the piston and the cylinder, it will cause serious “cylinder pulling” phenomenon, leading to early engine damage. I have personally dealt with several early engine failure caused by air filter damage, which is very dirty inside the engine, thick sludge attached to the parts, piston rings jammed, cylinders worn seriously, showing typical abrasive wear symptoms.

There are three kinds of air filters commonly used in automobiles: filter type, inertia type and oil bath type. According to different operating conditions and environment, we can choose different types of air filters or multi-stage filters.

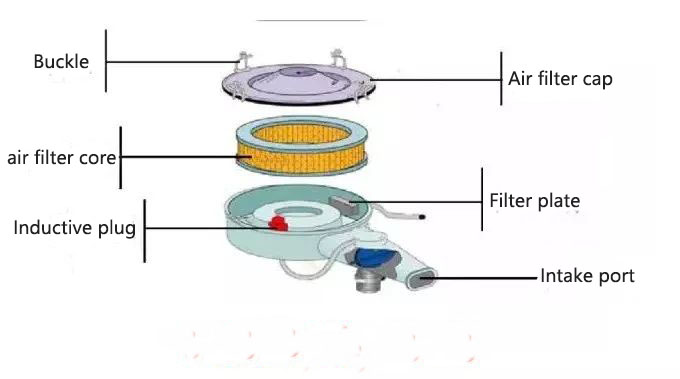

The filter type is to make air flow through metal filter mesh or filter paper, etc., to block impurities and adhere to the filter element. The vast majority of filter air filters are paper-based, and some models use relatively simple sponges or wire mesh. There is also an oil-based air filter on cars. It sprays a layer of grease on the fine wire mesh, and the filtering effect is better than that of paper. Its advantages are simple structure, easy maintenance, low intake resistance, and the disadvantage is that the filtering effect is limited. If the air filter breaks down, the dust will enter the engine directly. This type of air filter is enough for most cars and light vehicles. Even if there is only one set of air filter, it can filter out most of the dust and impurities in the air. The safety of the engine is guaranteed. If another set of air filters is installed, on the contrary, the intake resistance will be too large, the engine inflation efficiency will be reduced, and the power performance will be affected. The other two sets of air filters will occupy too much space in the engine compartment, and the layout will be more constrained. The so-called inertia means that before entering the filter element, air passes through a long pipeline with great curvature. When air circulates in this pipeline, it will rotate and rotate rapidly. At this time, because the density of impurities is higher than that of air, impurities can be separated from the air stream under the action of centrifugal inertia force to obtain pre-filtration. The impurities in the air will be removed by further filtration of the type air filter. If necessary, a set of filter type air filter can be added to make the filtering effect better. The advantages of this type are simple structure, good filtering effect, no impact on engine intake, but the disadvantage is that it can not cope with particularly harsh environment. This kind of air filter is mostly used in trucks running on highways, and two sets of air filter are used in some areas with large dust to ensure the filtering effect.

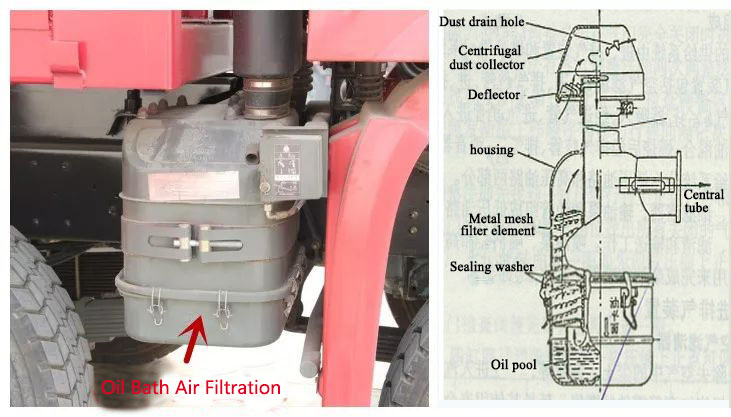

The so-called inertia means that before entering the filter element, air passes through a long pipeline with great curvature. When air circulates in this pipeline, it will rotate and rotate rapidly. At this time, because the density of impurities is higher than that of air, impurities can be separated from the air stream under the action of centrifugal inertia force to obtain pre-filtration. The impurities in the air will be removed by further filtration of the type air filter. If necessary, a set of filter type air filter can be added to make the filtering effect better. The advantages of this type are simple structure, good filtering effect, no impact on engine intake, but the disadvantage is that it can not cope with particularly harsh environment. This kind of air filter is mostly used in trucks running on highways, and two sets of air filter are used in some areas with large dust to ensure the filtering effect. If the use of automobiles is very harsh, such as in dusty mines, construction sites, metallurgical factories and other areas, ordinary air filtration is difficult to remove impurities from the air, which requires the use of oil-bath air filters. This type of air filtration is equipped with an oil pan at the bottom. The impurities are separated and adhered to the oil by the rapid rotation of air flow. The oil droplets which are stirred up flow through the filter core and adhere to the filter core. Air flow filter core can further absorb impurities, so as to achieve the purpose of filtering; the first layer of air filter is generally wire mesh, in its back will be through a set of paper filter type air filter, in order to play a better filtering role. Its advantage is that the filtering effect is very good, but its disadvantage is that the structure is complex, the intake resistance is large, it needs to be maintained frequently, and the space occupied is large. Generally, it is only used in dump trucks and construction machinery, but less used in other models.

If the use of automobiles is very harsh, such as in dusty mines, construction sites, metallurgical factories and other areas, ordinary air filtration is difficult to remove impurities from the air, which requires the use of oil-bath air filters. This type of air filtration is equipped with an oil pan at the bottom. The impurities are separated and adhered to the oil by the rapid rotation of air flow. The oil droplets which are stirred up flow through the filter core and adhere to the filter core. Air flow filter core can further absorb impurities, so as to achieve the purpose of filtering; the first layer of air filter is generally wire mesh, in its back will be through a set of paper filter type air filter, in order to play a better filtering role. Its advantage is that the filtering effect is very good, but its disadvantage is that the structure is complex, the intake resistance is large, it needs to be maintained frequently, and the space occupied is large. Generally, it is only used in dump trucks and construction machinery, but less used in other models.

In the truck’s filter air filter, in order to prevent the air filter from breaking down and leading to the direct entry of unfiltered air into the engine, a safety filter element is added to the air filter element. It is usually made of a layer of non-woven fabric, the filtering effect is not good, but if the outer layer of air filtration is damaged, it can also block most of the particulate matter. In this way, air from entering the intake pipe needs to pass through inertia filter, oil bath filter, ordinary filter, paper filter, safety filter, and almost no impurities.

Air filters do not have a clear replacement and maintenance cycle, we are generally based on the local environment and the air quality of the operation area to appropriate maintenance. For ordinary small cars, blowing every 5,000 kilometers and replacing every 10,000 kilometers is enough; for trucks and engineering machinery, blowing every 50 hours and blowing three times is required; for dump trucks using oil bath air filter, blowing air filter core at least every 50 hours, checking and adding oil surface every 200 hours and every 200 hours. Change the filter element once, if the conditions are particularly bad, the cycle will be shortened, and some even need to be cleaned up once a day.

Post time: Feb-27-2019