Nowadays, there is a popular saying in the market that when purchasing filters, there are more goods than three. We should compare the weight of products. The heavier the weight, the better the quality. Because heavy weight means enough material, light weight means jerry-building.

This may seem reasonable, but can it really stand on its feet?

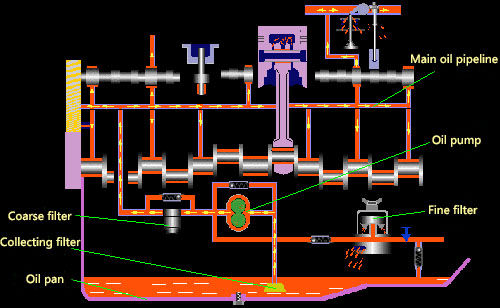

As we all know, the main function of filter in automobile is to filter air, fuel and oil. Therefore, to measure the quality of a filter, it is mainly based on the following indicators: rated flow rate, filtration efficiency, dust (ash) capacity, service life and sealing performance. The above technical indicators are not directly proportional to the weight of the filter.

For example, the rated flow rate, filtration efficiency, dust (ash) capacity, service life and other indicators, mainly depends on the technical characteristics and quality of the filter material and the forming structure of the filter element, which has no direct relationship with the weight of the filter.

The selection of material and the structure of filter element are determined by the design requirement of the filter itself, and the heavier the material, the more suitable the type of vehicle used.

For example, if the same type of oil filter is used, the overflow resistance and flow rate will be increased greatly, which will increase the energy consumption of the vehicle in the process of driving, and even fail to meet the demand of the engine for oil flow, resulting in insufficient lubrication of the oil.

Therefore, the heavier the selection, the better.

For example, the sealing performance of rotary filter mainly depends on the performance of the sealing ring and the strength of the shell, which is not the heavier the better. Some people think that the heavier the rotary filter is, the thicker the shell material used, the better the sealing performance.

In fact, this statement is incomplete. Each filter has a suitable working pressure range, as long as the pressure bearing capacity of the filter has enough surplus for its working pressure. It is unreasonable from the point of view of environmental protection and cost-effectiveness to choose too thick materials instead of increasing unnecessary costs, and at the same time to bring extra loads and increase energy consumption to vehicles.

In addition, the performance of the sealing ring and the strength of the shell largely depend on the material chosen and the structural design of the parts. By optimizing material and product design structure, while ensuring product quality and reliability, making products lightweight, environmentally friendly and more cost-effective, is it not a good choice?

Post time: Mar-06-2019