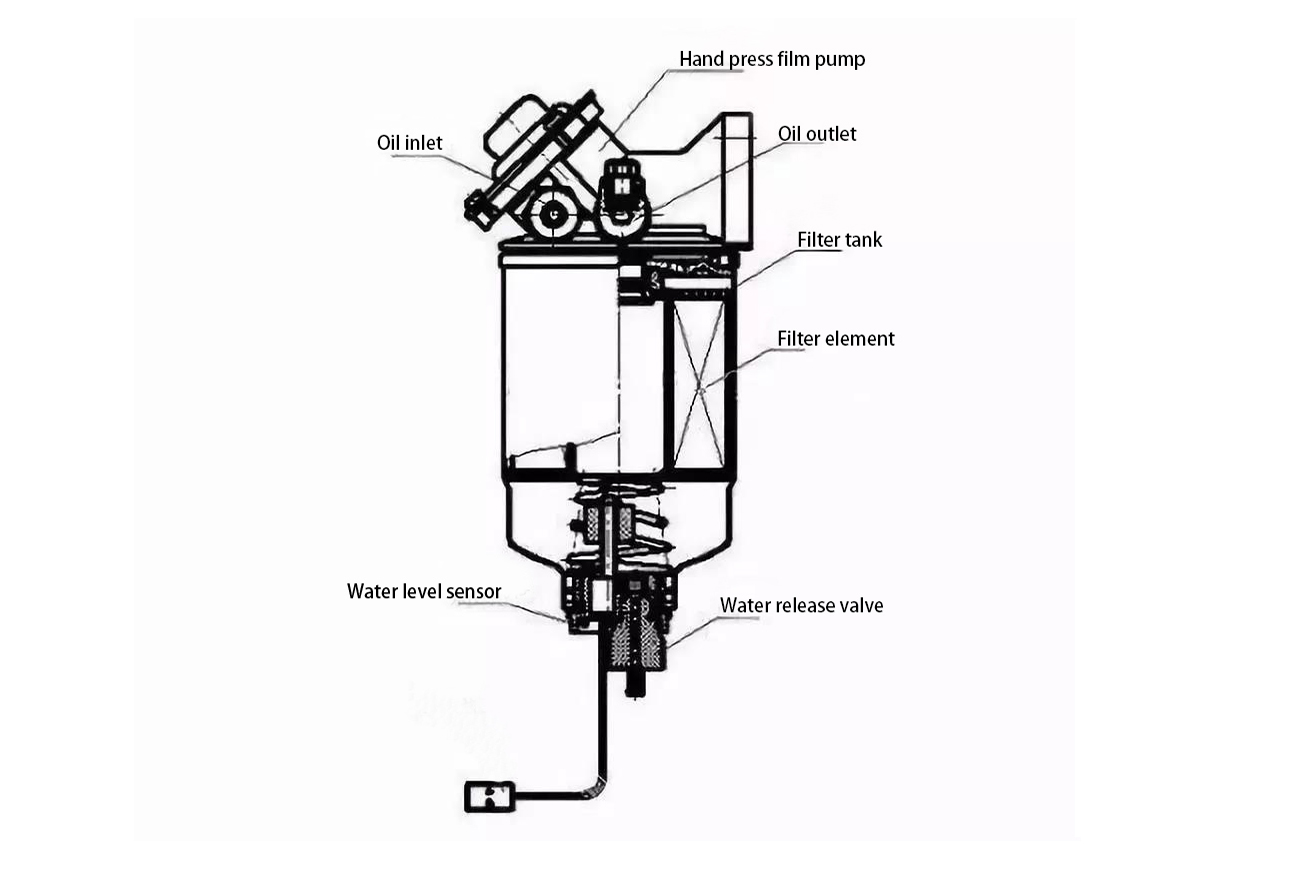

1. Diagram of Diesel Filtration System

2. The structure of diesel filter

The diesel filter is mainly composed of hand oil pump (filter seat), filter components, water level sensor, temperature sensor, heater, sealing ring, pipe joint and other components, in which the core filter element is the filter element.

Third, the purification method of the filter element and its working principle

(1) Screening effect

When the fluid passes through the porous body, impurity particles with a particle size in the fluid are intercepted by the porous body on the surface; particles with a diameter smaller than the porous body pass through the porous body with the fluid.

The screening effect is the basic principle of the filter. General wire mesh filter materials and surface filters are filtered according to the screening effect. Since the pore size of the filter material and the diameter of the impurity particles are not completely circular, they are both equivalent pore size and equivalent particle size. Therefore, the particle size it intercepts is much smaller than the pore size of the filter material.

(2) Brownian motion (the phenomenon that suspended particles keep making random motions is called Brownian motion) and the aggregation of particles and the foreign particles in the adhering fluid make irregular Brownian motion all the time, when they move to the pores of the porous body When the wall is adhered, it stays in a small area on the airlock and is filtered by the porous body.

Impurity particles may also collide with each other due to Brownian motion and liquid vibration. Under the effect of surface binding force, the apparent diameter of the particles gradually increases. As we all know, the surface capacity of particles increases with the decrease of particle size (inversely proportional relationship) and is proportional to the square root of the contact area between particles, so tiny particles are easy to aggregate and not easy to disperse.

(3) Use filter media to separate the “affinity” and “distance” effects of media (such as oil and water)

When the oil flow with tiny water droplets enters a kind of filter material that is “pro-” oil “sparse” water (such as microporous filter paper with a resin content of 27 ~ 32%), due to the “affinity” of the filter material to oil , The oil flow smoothly passes through the pores of the filter material; due to the “distant” performance of the filter material to water, tiny water droplets cannot smoothly pass through the pores of the filter material.

Due to the infiltration effect of the tiny water droplets on the filter material fluff, the tiny water droplets stay on the filter material fluff. The tiny water droplets intercepted gradually increased, causing them to coalesce into large droplets. Under the action of oil pressure, the water beads are pressed against the wedge-shaped passage of the filter element, forming larger water droplets. Under the lease of oil pressure, after the water drops pass through the filter material, under the effect of its own quality, the country settles and falls into the water collection cup.

At present, the most widely used in the world is to separate water from fuel oil. The better the “sparse” water performance of the filter material, the better the effect of separating water.

All our high-end filter products use original filter materials, which have higher filtration accuracy and more effective protection of the engine; high-strength galvanized shell, anti-corrosion, high pressure resistance, safer and more reliable use; all series use oil resistance High temperature 130 ℃, low temperature resistance -45 ℃ high quality sealing ring; professional customized original oil cup, oil resistant, high and low temperature resistance, longer service life.

Post time: Apr-24-2020