The oil-water separator on the diesel engine, because there is water in the diesel oil, the oil-water separator uses the different specific gravity of oil and water. After passing through the separator, the water is stored underneath. When the water is stored to a certain amount, the indicator light will light up and alarm. The oil-water separation filter element is mainly designed for oil-water-liquid separation. It contains two filter elements, namely: coalescing filter element and separation filter element.

For example, in an oil dewatering system, after the oil flows into the coalescing separator, it first flows through the coalescing filter element, which filters out solid impurities and coalesces extremely small water droplets into larger water droplets. Most of the coalesced water droplets can be separated and removed from the oil by their own weight, and then settled in the sump.

Most of the coalesced water droplets can be separated and removed from the oil by their own weight, and then settled in the sump. Then the oil flows through the separation filter element. Because the separation filter element has good lipophilic and hydrophobic properties, the water is further separated. Finally, the clean, water-free oil flows out of the coalescing separator.

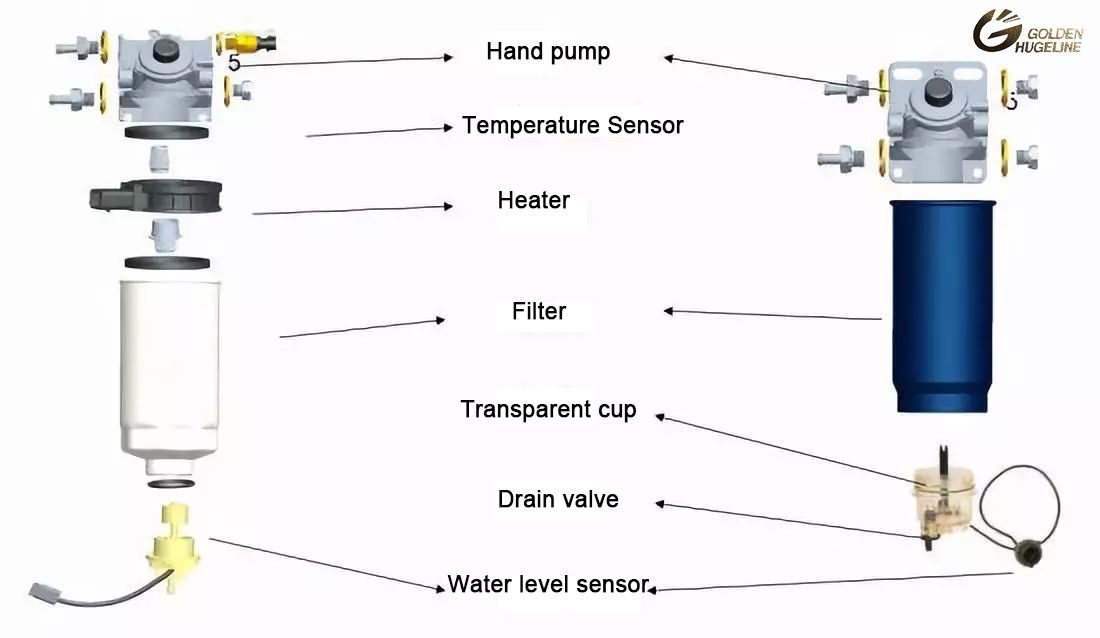

The oil first enters the lower part of the filter housing from the inlet pipe, and then flows from the outside to the inside of the filter element. At this time, the coarser particles will immediately settle down and be discharged by the drain valve, and the smaller particles are intercepted by the filter element. Finally, after the clean oil is collected by the filter element tray, it flows out of the coalescing separator from the outlet pipe. As the amount of oil to be processed increases, the contaminants deposited on the filter element will cause the pressure difference of the coalescer to rise.

When the pressure difference rises to 0.15Mpa, it indicates that the coalescing filter element has been blocked and should be replaced. The oil flows into the first-level tray from the oil inlet of the coalescing separator, and then diverges into the first-level filter element. After filtration, demulsification, water molecules grow up, and coalesce, the impurities are trapped in the first-level filter element. The water droplets settle in the sedimentation tank, and the oil enters the secondary filter element from the outside to the inside, collects in the secondary tray, and flows out from the outlet of the coalescing separator.

The material of the secondary filter element is hydrophobic, and the oil can pass smoothly, while the free water is blocked from the filter element, flows into the sedimentation tank, and is discharged through the sewage valve.

Post time: May-08-2021