Truck engines are very sophisticated components, and very small impurities can damage the engine. When the air filter is too dirty, the intake air of the engine will be insufficient, the fuel combustion will be incomplete, resulting in the instability of the engine, power decline and fuel consumption increase. At this time, as the guardian of the engine, the air filter is particularly important in maintenance.

In fact, the maintenance of air filters is mainly based on the replacement and cleaning of filter elements. The air filters used in engines can be divided into three types: inertia type, filter type and comprehensive type, which can be divided into dry type and wet type according to whether the filter material is oil-soaked or not. We describe several common air filters on the market.

Maintenance of dry inertial filter

Dry inertia air filter consists of dust cover, guide vane, dust outlet, dust cup and so on. Attention should be paid to maintenance:

- Check and clean the dust holes on the centrifugal dust removal cover regularly, remove the dust adhering to the guide vane, and pour out the dust in the dust collection cup (the amount of dust collected in the container shall not exceed one third of its volume). Installation should ensure the sealing of the rubber gasket at the joint, and there should be no air leakage. Otherwise, the short circuit of air flow will reduce the rotating speed of air and the dust removal effect will be greatly reduced.

- Dust removal cover and diversion should keep the correct shape. If there is a knock, it should be shaped in time so as not to change the flow direction of the original design and reduce the filtering effect.

- It is not allowed for some drivers to refuel the dust collector cup (or disk). Because the oil is easy to splash to the dust outlet, diversion vane and other parts, so that this part of the dust adsorption, and ultimately reduce the ability of filtration and separation.

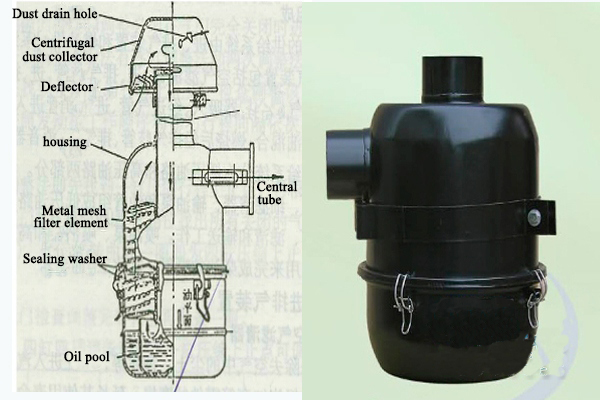

Three-stage integrated air filter structure

Three-stage integrated air filter structure - Maintenance of Wet Inertial FilterWet inertial air filter consists of central pipe, oil tank and so on.

- Clean oil pan and change oil regularly. When changing oil, the viscosity of the oil should be moderate. If the viscosity is too high, the filter screen of the filter device will be blocked easily, and the intake resistance will be increased; if the viscosity is too small, the ability of oil to adhere to dust will be reduced; at the same time, the splashed oil will be easily absorbed into the cylinder to participate in combustion and generate carbon deposit.

- The height of oil surface in oil tank should be moderate. Oil should be added between the upper and lower lines of the oil pan or at the arrow mark. Low oil level, insufficient oil, poor filtering effect; high oil level, excessive oil, easy to be sucked into the cylinder combustion, and can lead to “flying” accident.

Maintenance of dry filter

Dry air filter device is composed of paper filter element and sealing washer. Attention should be paid in use:

- Regular inspection and proper cleaning. When removing the dust on the paper filter element, brush the dust on the surface of the filter element along the fold direction with a soft brush, and gently tap the end face to make the dust fall off. When doing the above operation, clean cotton cloth or rubber plug is used to block both ends of the filter element to blow out the dust adhering to the outside surface of the filter element from the inside of the filter element by compressed air machine or air pump (air pressure should not exceed 0.2-0.3 MPA to prevent damage to the filter paper).

- Do not use water or diesel oil or gasoline to clean the paper filter element, otherwise the pore of the filter element will be blocked and the air resistance will be increased. At the same time, diesel oil is easy to inhale the cylinder, resulting in overrun after loading.

- When it is found that the filter core is damaged, or that the upper and lower ends of the filter core are uneven, or that the rubber seal ring is aged, deformed and damaged, new parts should be replaced.

- When installing, attention should be paid to the gaskets or sealing rings in the joint parts not to be missed or misfitted, so as to avoid short circuit of air. Don’t screw the butterfly nut too tightly to prevent the filter from crushing.

Maintenance of Wet Filter

This device is mainly composed of metal filters immersed in oil. Attention should be paid to the use of the device.

1. Wash the dust on the filter screen regularly with diesel or gasoline.

- When assembling, first soak the filter with oil, and then assemble after the excess oil droplets have been exhausted. The cross skeleton on the filter tray of cake filter should be overlapped and aligned during installation, and the inner and outer rubber rings of the filter should be well sealed to prevent short-circuit of air intake.

Desert Dual-stage Air Filter

With the development of truck technology, paper-core air filters are more and more widely used in engines. Compared with oil-bath air filters, paper-core air filters have many advantages:

1. The filtration efficiency is as high as 99.5% (oil-bath air filter is 98%) and the dust transmission rate is only 0.1% – 0.3%.

2. The structure is compact and can be installed in any direction without restriction of the layout of vehicle parts.

3. Oil is not consumed during maintenance, and a large amount of cotton yarn, felt and metal materials can be saved.

4. Low weight and low cost.

Post time: Jan-11-2019