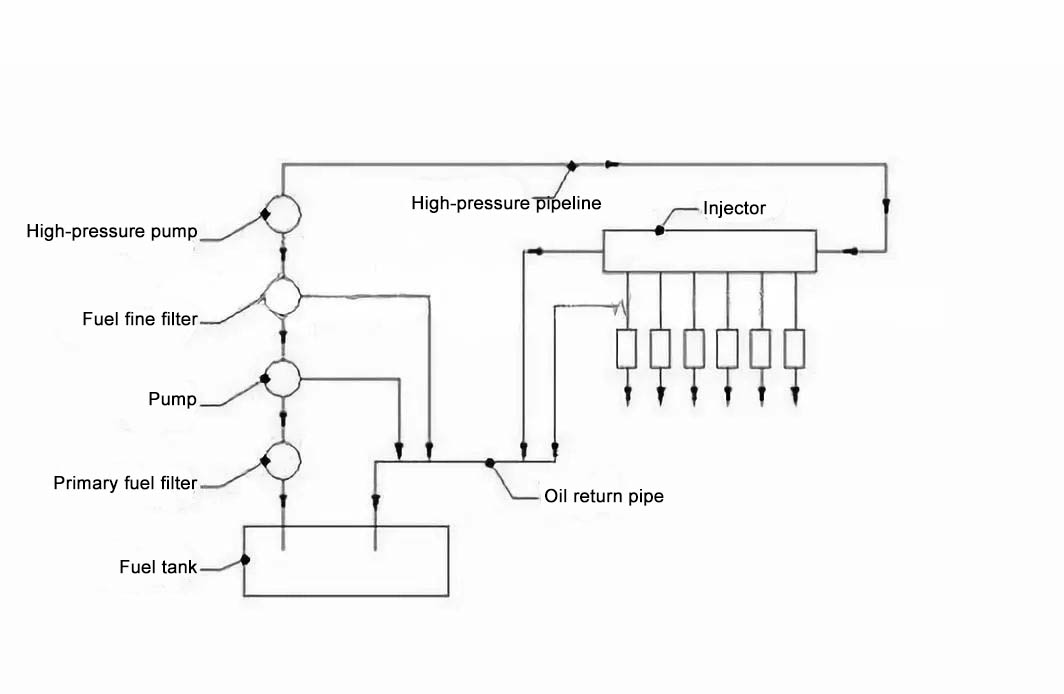

First, diesel filtration system diagram

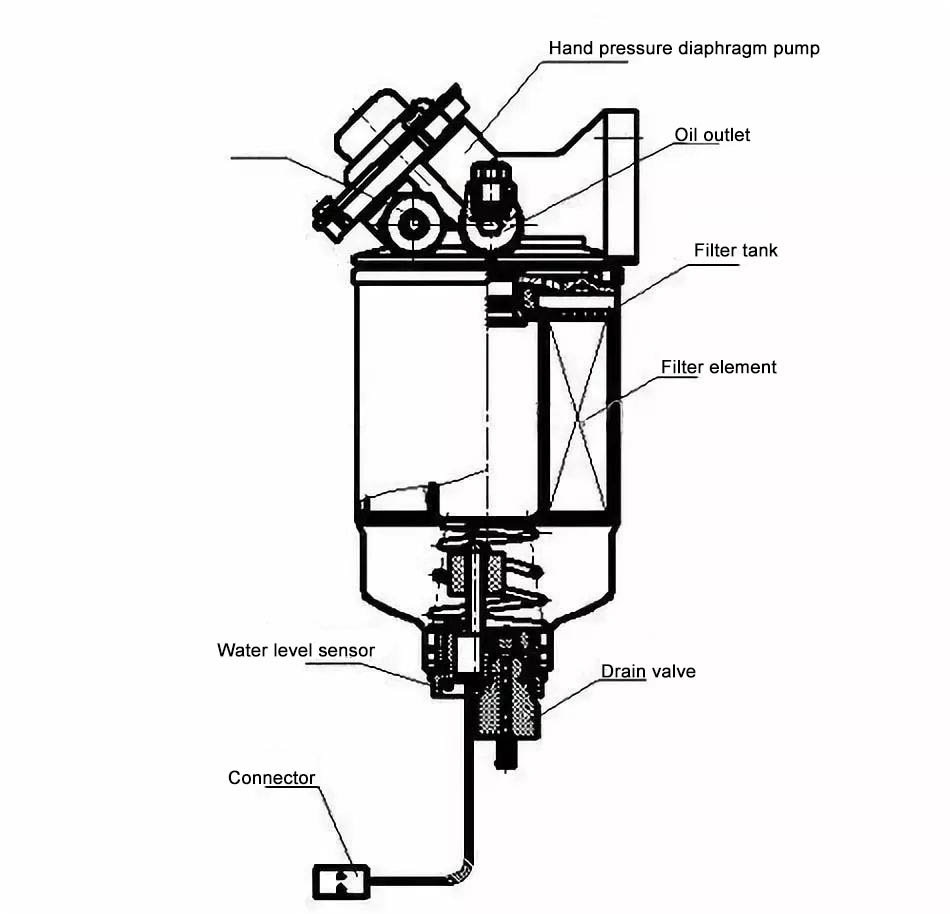

Second, the composition of the diesel filter

The diesel filter mainly consists of a hand oil pump (filter seat), a filter component, a water level sensor, a temperature sensor, a heater, a sealing ring, a pipe joint, and the like, wherein the filter core member is a filter element, see a structural drawing.

Third, the filter purification method and its working principle

(1) Screening effect

When the fluid passes through the porous body, the impurity particles of the particle size in the fluid are intercepted by the porous body on the surface; the particles having smaller diameter particles than the porous body pass through the porous body with the fluid.

The screening effect is the basic principle of the filter. The general wire mesh filter and surface filter are filtered according to the screening effect. Since the pore diameter of the filter medium and the diameter of the impurity particles are not round, they are equivalent pore diameters and equivalent particle diameters. Therefore, the particle size it intercepts is much smaller than the pore size of the filter material.

(2) Brownian motion (the phenomenon that the suspended particles continuously move irregularly is called Brownian motion) and the aggregation of particles and the impurity particles in the adhering fluid make irregular Brownian motion all the time, when they move to the pores of the porous body. The wall is adhered to a small area that is retained in the air gap and is filtered by the porous body.

Impurity particles may also collide with each other due to Brownian motion and liquid vibration, and the apparent diameter of the particles gradually increases under the surface bonding force. It is well known that the surface ability of a particle increases two (inverse relationship) as the particle size decreases, and is proportional to the square root of the contact area between the particles, so that minute particles are easily aggregated and are not easily dispersed.

(3) Separation of “affinity” and “distance” effects of media (such as oil and water) using filter media

When the oil flow with tiny water droplets enters a kind of “pro-oil” oil “sparse” water filter material (such as microporous filter paper with resin content of 27~32%), due to the “affinity” of the filter material to the oil The oil flow smoothly passes through the micropores of the filter material; due to the “distance” of the filter material to water, tiny water droplets cannot smoothly pass through the micropores of the filter material.

Due to the wetting effect of the tiny water droplets on the filter fluff, the tiny water droplets are retained on the fluff of the filter material. The tiny water droplets that are intercepted gradually increase, causing them to gradually coalesce into large water droplets. Under the action of oil pressure, the water droplets are pressed against the wedge-shaped passage of the filter element to form larger water droplets. Under the rent of oil pressure, after the water droplets pass through the filter material, it settles in the countryside under the effect of its own mass and falls into the water collecting cup.

The most widely used in the world today is to separate water from the fuel. The better the “sparse” performance of the filter material, the better the effect of separating the water.

Post time: Aug-23-2019