The oil filter is located in the engine lubrication system. Its upstream is the oil pump, and downstream is the parts of the engine that need lubrication. The function is to filter harmful impurities in the oil from the oil sump, and supply the lubricating oil to the motion pair such as the crankshaft, the connecting rod, the camshaft, the supercharger and the piston ring to play the role of lubrication, cooling and cleaning. Extend the life of these components.

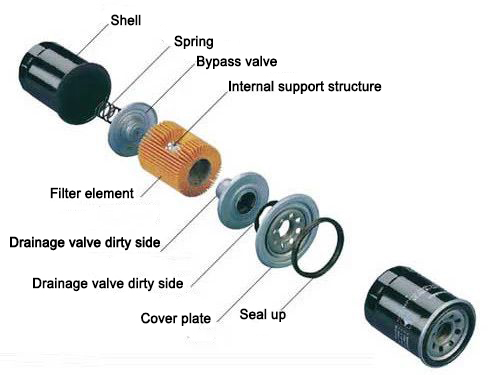

Before the 1980s, the oil filters used in the national engines were mostly interchangeable. The filter of this structure is to put the filter element and other parts, such as a spring, a sealing ring and the like into a metal casing, and connect the casing filter element and the like to a metal filter seat through a tie rod.

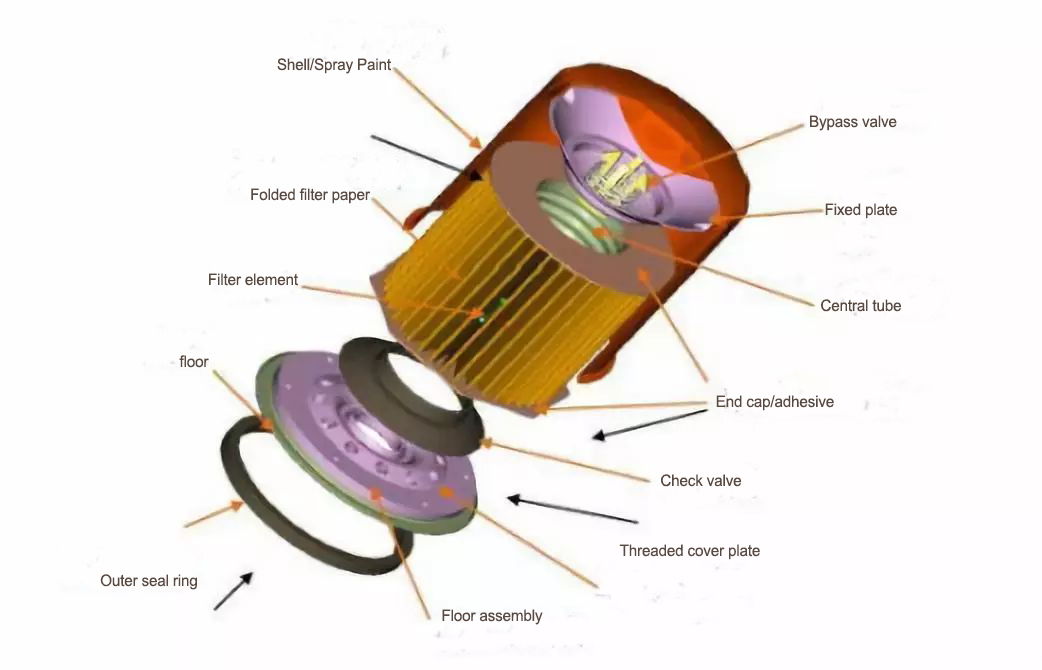

It has the advantage of low cost of use and only requires regular maintenance and replacement of the filter element. The shortcoming is that there are too many sealing points, and the maintenance and replacement of the filter element may leak parts, which is easy to cause loopholes, and the replacement is troublesome. Since the early 1980s, the filter plant has been the first domestically introduced spin-on filter production line from Italy, and the spin-on filter has been gradually approved for domestic OEMs. The filter is characterized by a check valve, a bypass valve and only one sealing point, which is completely replaced, which greatly improves the sealing property and is easy to replace. The filter material is mostly imported filter paper, so the filtration efficiency is high. The flow resistance is small and the life is long.

Nowadays, all the cars in the world use this type of oil filter. Most of the mini-cars, as well as large, medium and small passenger cars, light and medium-duty trucks, as well as some heavy-duty trucks and agricultural vehicles, are spin-on. Oil filter.

The spin-on oil filter is provided with a paper filter in a closed casing with an oil inlet and an oil outlet, and upper and lower end covers are respectively glued on the upper and lower ends of the paper filter. Between the upper and lower ends of the cover, a porous central tube is supported to support the paper filter element to prevent the paper filter element from being deformed when the oil pressure is large. Meanwhile, an oil outlet is provided in the middle position of the upper end cover, and the oil is distributed around the upper end cover. An oil check valve is arranged between the holes, a bypass valve is arranged on the lower end cover, and a support spring is arranged between the lower end cover and the filter housing, and the paper filter element is supported by the spring to make the upper end cover The oil outlet is in close contact with the oil outlet on the filter housing.

The paper filter element is designed to use the micropores that are densely covered around the body to filter out harmful impurities in the oil. The bypass valve is to prevent the engine from being cold-started or the paper filter element is blocked by impurities, so as to avoid the engine being dry due to lack of oil. Friction, so that the oil can be circulated back to the engine without passing through the paper filter; the check valve is used to prevent the oil filter from being emptied after the engine is turned off, and to avoid damage caused by lack of lubricating oil when the engine is restarted again. Settings.

How does the spin-on oil filter work? When in use, the oil enters the outer cavity of the paper filter in the filter housing through the oil inlet under the action of the oil pump, and then passes through the paper filter through the microfiltration of the paper filter to filter out the harmful impurities in the oil, and the relatively clean oil enters the paper. The central tube inside the filter element is then circulated back to the engine through the oil outlet of the central tube to complete a cycle.

Post time: Apr-25-2019