The normal maintenance project of the car includes the replacement of the three filters, which refers to the air filter, the oil filter, and the fuel filter. As people pay more attention to the interior environment, air conditioner filters have become one of the conventional replacement parts, called the fourth filter. Regular replacement and cleaning of the filter is critical to the maintenance of the car. The replacement of the oil filter and the fuel filter requires a professional, but the air and air conditioner filters are few items that can be replaced or cleaned by themselves, and the difficulty is small. DIY can save a lot of maintenance costs. search for).

This article focuses on the application of polyurethane in air filters today.

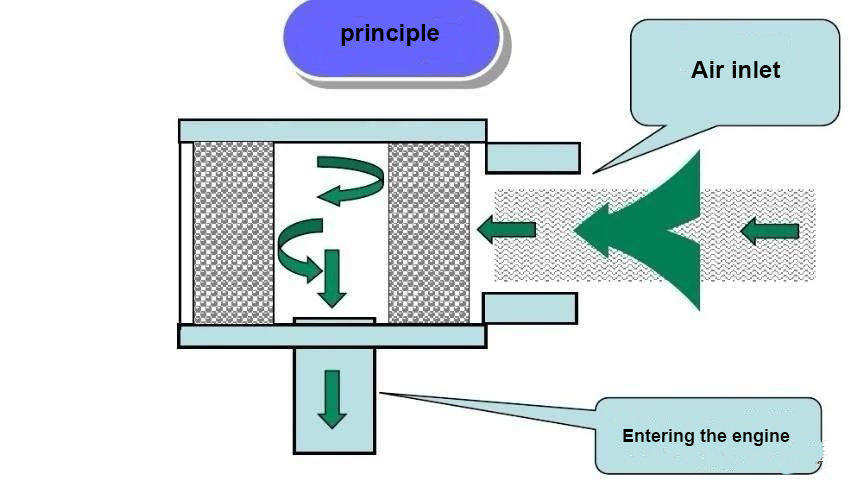

First, let’s look at the working principle of the air filter: the car engine needs to suck in a large amount of air during the working process. The air needs to filter the dust through the air filter to avoid the wear of the particles on the piston set and the cylinder, thereby reducing the engine. life. Therefore, the air filter components are small, but have a significant impact on the long-term performance of the car.

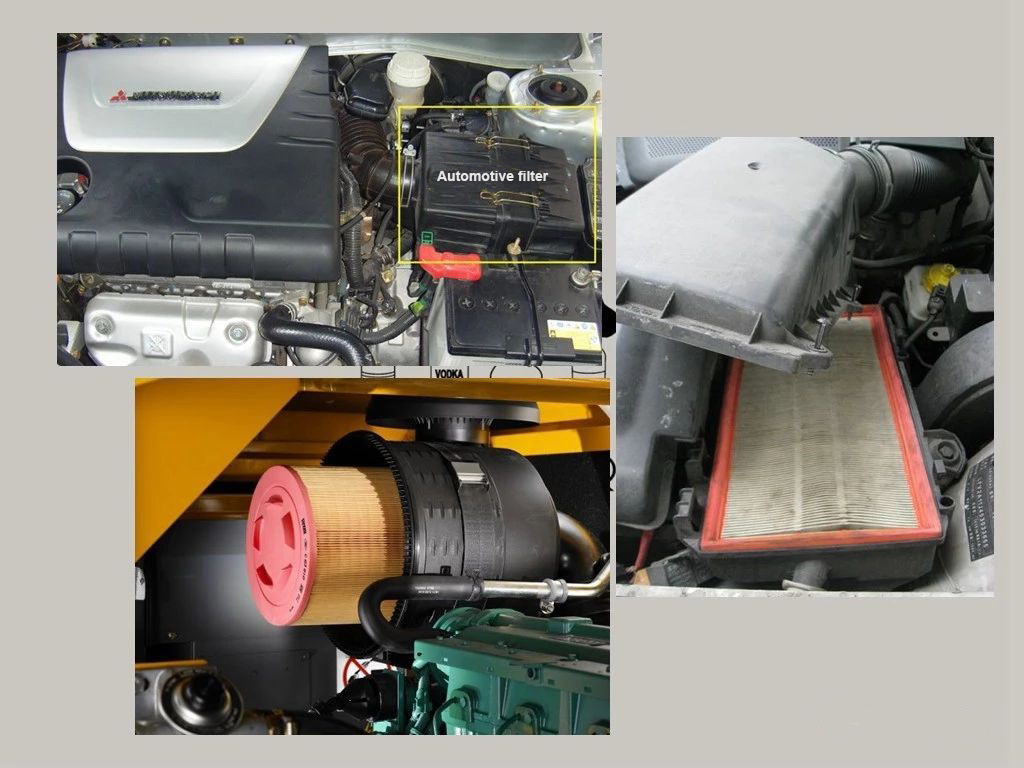

The air filter has many types and shapes, but the main structure is very simple, and it is composed of a filter element and a casing (end cover/frame). The filter element is usually divided into filter paper and polyurethane, and the material of the shell is iron, PP, polyurethane and the like.

Filters for trucks, trucks, construction vehicles, etc. are generally composed of a filter element and an end cap. The filter material is filter paper or polyurethane. Filter paper is a dry filter. Polyurethane is used in wet filter. It is made of soft, porous sponge-like polyurethane. It can be used in oil immersion or oil bath when it is installed. Such filter can be used repeatedly, as long as it can be cleaned, but the filtration effect is not as dry.

The filter for a family car is generally composed of a dry filter element and a polyurethane frame. The filter material is filter paper or non-woven fabric. It can increase the air passage area by processing many small folds. When it is slightly fouled, it can be blown off by compressed air. However, when the stain is serious, it must be replaced. It is generally recommended to change 10,000 km. .

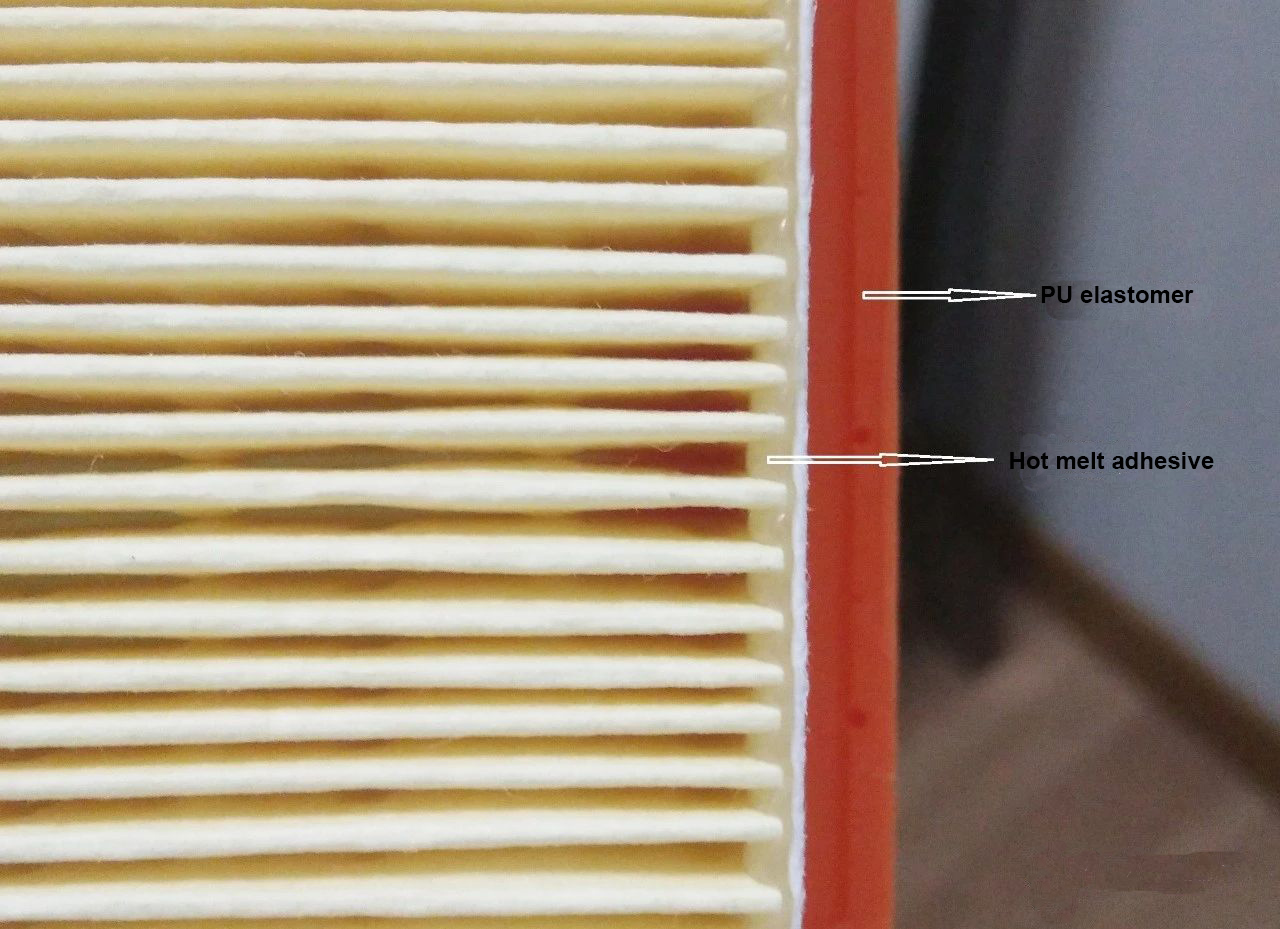

Understand the above basic knowledge, and then talk about the application of polyurethane in air filter in three forms: In the form of hot melt adhesive

In the form of hot melt adhesive

(1) The edge seal after folding the filter paper requires hot melt adhesive. The following picture shows the application of two hot melt adhesives:

(2) The filter end cover is an iron cover or a PP cover filter. During the manufacturing process, the filter element and the end cover and the sealing ring are bonded by hot melt adhesive.

Reference process:

1Assemble the filter element according to the process.

2 Clean the surface of the filter cover to remove oil, dust, and thoroughly dry. Do not have any foreign matter such as oil, moisture, etc. on the surface, so as not to affect the bonding strength.

3Inject a proper amount of adhesive into the rotating filter cover to apply the flat surface of the adhesive to all parts of the filter cover.

4 Insert the filter element into the filter element cover, check the surface of the two glue parts, and ensure that they are completely in contact with the pressure at the top.

5 After curing for about 2 hours, it is turned over and glued to the other end cover. After 24 hours, it can be completely dried and then packaged. After curing for 3 days, it is shipped.

6 parts of the filter should be added to the upper end of the strip, can be added in the fifth procedure (normal temperature curing adhesive can also use heat curing adhesive) The filter element is a polyurethane material

The filter element is a polyurethane material

Generally, wet air filter elements are used on construction machinery and heavy trucks. The material is soft and porous sponge-like polyurethane, which has been described above and will not be described again.

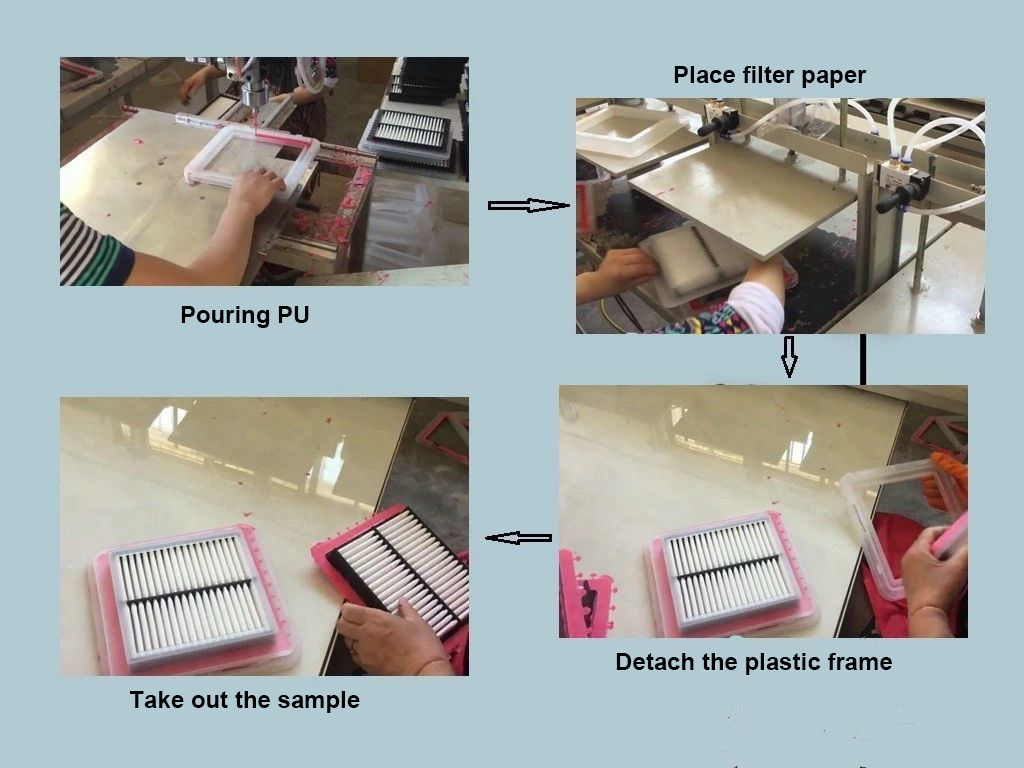

The housing (end cover / frame) is a polyurethane material

The housing is produced by casting a PU elastomer, which eliminates the iron end caps and rubber seals of the air filter and is the ideal product for the production of a wrench air filter. The housing has an end cover and a frame, each having a different production process.

End cap type: By pouring the mixed A\B material into the rotating iron plate or plastic plate, and then putting the filter element under pressure, the disc can be detached after a few minutes to obtain the air filter.

Frame type: There are 2 production modes:

1 Similar to the end cap type, pouring A\B material into the plastic frame, then applying pressure on the filter paper, and then removing the plastic frame to obtain the air filter after a few minutes.

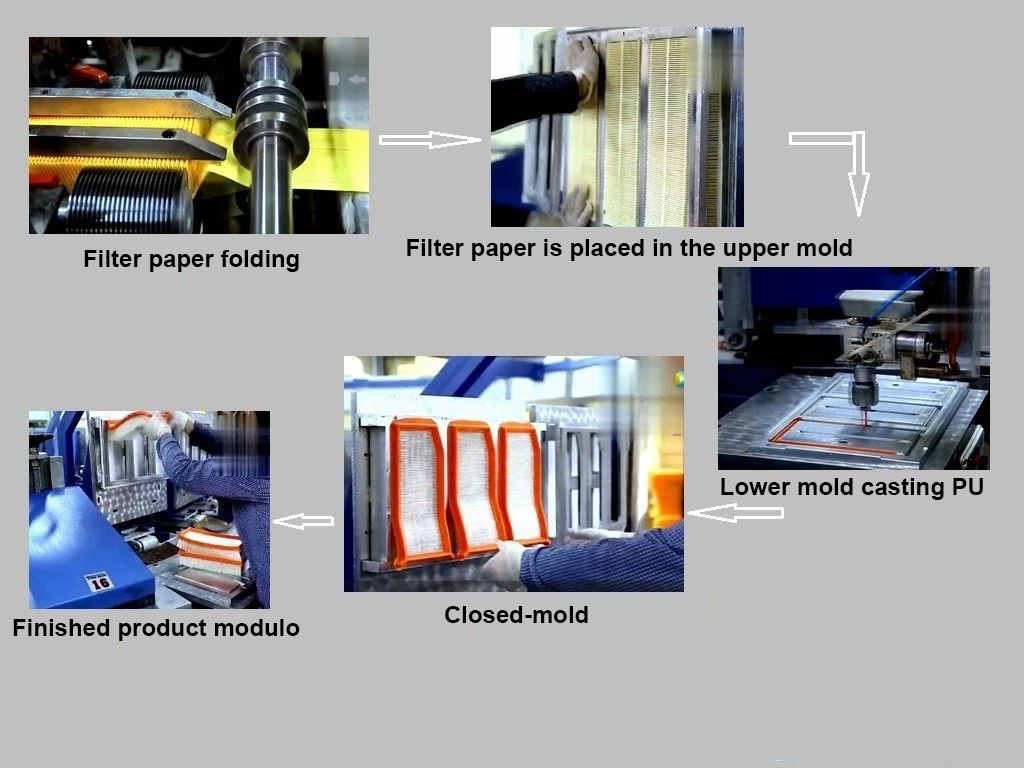

2 by closed mold (usually aluminum film) production, the upper mold is placed in the prepared filter paper, the lower mold is previously wiped or sprayed with a special release agent, then A\B material is poured, then the mold is closed up and down, and the mold is opened in a few minutes. The molded air filter can be removed.

Post time: May-14-2019